Matexis checks your anti-corrosion paint installations.

Anti-corrosion inspection

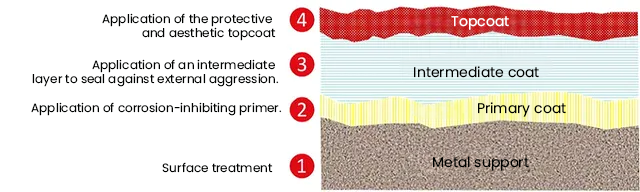

Paint systems are generally made up of several layers performing different functions and applied after appropriate surface preparation (dry abrasive blasting, UHP pressurised water blasting, etc.). For engineering structures, the systems generally have three layers which perform the following functions:

The ACQPA FROSIO Level 3 certified inspector will visit your premises or your service providers, in

compliance with the applicable safety rules, to guarantee :

- Compliance with order requirements

- Compliance with good practice and in accordance with professional standards for anti corrosion treatment.

The inspector will be equipped with all the necessary inspection equipment to carry out the required

checks. The inspector's role is to stop any work in progress if the work is not being carried out properly, or if it does not comply with the rules of the trade or safety regulations.

Quantitative and qualitative verification of the

parts to be painted : number of parts,

conformity of the constructive provisions of the

supports such as the preparation of angles and

welds, access, etc.

Checking the climatic conditions at each stage and the conformity of the products to be applied : Product validity, CIR sheet, storage, temperature and mixing before application, checking dew point, temperature and humidity, etc.

Additional tests : adhesion tests using tensile tests or grid tests, Holiday test film porosity, PIG test, salt spray tests.

Surface preparation : degree of care in preparation, type of grit, grit conductivity, dust level, chloride measurement, measurement of soluble contaminants using the Bresle test, verification of absence of oils and greases, measurement or verification of roughness using Press O film or Visio tactile comparators.

Paint system application : wet film thickness, coverage time, pot life, MEK test, number of coats and dry film thickness.